- Home

- Our Projects

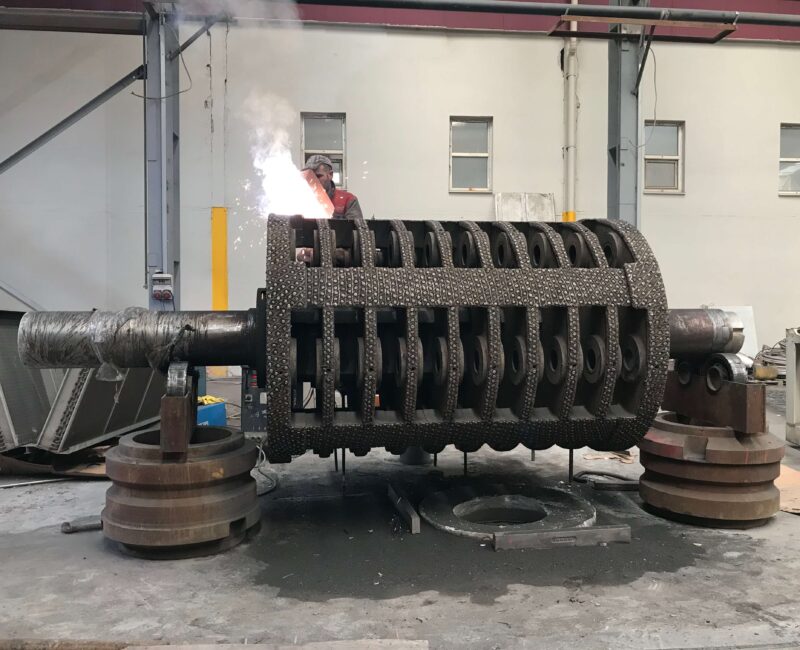

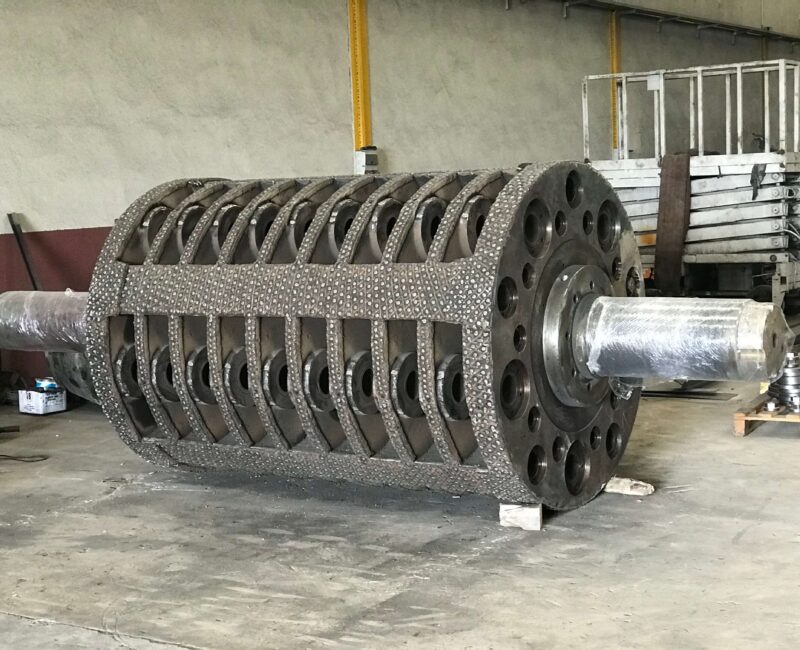

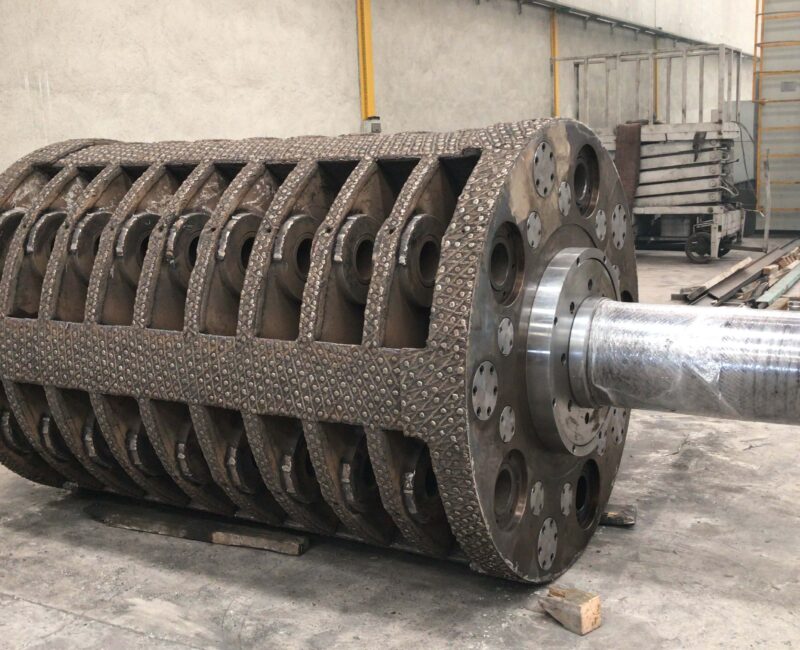

Revision and Maintenance

For details of our revision, maintenance and modernization services...

- Fields of Activity

- About Us

- Contact

- Our Projects

Revision and Maintenance

For details of our revision, maintenance and modernization services...